- by James Rousse

The Breitspurbahn: Adolf Hitler’s Train of Dreams

Part 4. Fuel Options

As discussed in the first article that included sections 1—3 about the Breitspurbahn, if a new Breitspurbahn network were to be built, then opting to make the locomotives that pull these trains powered by steam would make the most sense. As mentioned previously, new designs for steam trains that were pioneered by Livio Dante Porta and Andre Chapelon offer the cheapest overall maintenance and fueling costs, along with the most flexibility for fueling options. New and improved steam train designs also offer the benefit of not needing very sophisticated or centralized infrastructure to build the needed equipment nor is centralized and sophisticated infrastructure needed to continually operate the equipment after is has been put into service. Concerning the best fueling options for steam trains, coal is the fuel that emerges as the cheapest option.

The previous article about Breitspurbahn trains also mentioned that the Gas Producer Combustion System or GPCS that was invented by Livio Dante Porta offers the possibility of burning low-carbon types of coal that have traditionally offered too little energy per kilogram to power trains while also producing too much soot when burned, so offering too little energy and producing too much soot made many types of coal previously unworkable as fuel options for trains. Porta’s GPCS fire box systems burn the smoke that is given off from the primary combustion of coal, so these firebox systems burn much more efficiently and produce a whole lot less soot.

Soot accumulation on the inside of a train boiler’s fire tubes poses a huge problem because soot deposits are laborious to clean and accumulated soot deposits also greatly reduce the efficiency of any steam train’s boiler. To make matters worse, soot particles that rapidly fly through the fire tubes inside of a steam train’s boiler also act as a sort of continual moving grit that speeds up the wear on the fire tubes. The process of frequent fire tube cleaning or “tube punching” is necessary when regular coal is burned, but the cleaning process for fire tubes also greatly speeds wear on these components. In standard train fire box designs, up to 50% of the coal burned in the boiler leaves the train’s chimney as soot, which is really downright wasteful, polluting, and inefficient; however, Porta’s GPCS design makes much more efficient use whatever fuel that a steam train might burn.

A GPCS fire box offers more efficient combustion, so this boosted combustion efficiency allows steam trains to get sufficient power to move by burning types of coal that have traditionally never offered enough combustion energy for anything other than stationary power plants, and GPCS fireboxes also eliminate the need for laborious cleaning routines on boiler fire tubes. Other innovations that Porta has incorporated into his steam train designs in addition to his innovative GPCS boiler designs have created trains that use 30% less coal than conventional designs; admittedly, a 30% boost in overall train efficiency does not sound all that impressive, but this boost in fuel efficiency does open the door for burning Sub-Bituminous and Lignite coal as train fuel, which was not possible before Porta introduced his GPCS firebox design.

Image above courtesy of the Coalition for Sustainable Railroad’s website.

Image above courtesy of the Coalition for Sustainable Railroad’s website.

Coal Prices

Here are the September 2021 coal prices as listed by the website eia.gov:

Lignite- Lignite is a type of coal that is brown in color and contains between 25—35% carbon by weight. This type of coal is typically only used in power plants due to its low energy content, high moisture content, and its tendency to leave heavy soot deposits. As of 2020, Lignite only accounted for around 9% of all coal mined in the United States.

Cost: $22.16 per ton.

The image of a chunk of Lignite coal that is featured above is featured courtesy of marksteinmetz.photoshelter.com

Sub-Bituminous- This type of coal contains 35—45% carbon by weight and is not as dirty to burn and as low in energy output per ton as lignite; however, this type of coal is still considered to be substandard when compared to regular Bituminous coal.

Cost: $14.43 per ton.

The image of sub-bituminous coal that is featured above comes courtesy of Pinterest.com and Peggy Connor’s account.

Bituminous- This type of coal contains 45—86% carbon and is the most common type of coal that is used to power trains. This type of coal is commonly used in blacksmith forges and it is also the type of fuel that typically stokes steel mills.

Cost: $50.05 per ton.

The image above shows a piece of bituminous coal. Image courtesy of wikipedia.org

Anthracite- This type of coal is shiny and deep black in color and has a carbon content of 87—97% carbon by weight. Anthracite holds the most energy per kilogram, and this type of coal also burns with a nice blue flame which produces the lowest amount of soot and smoke for any type of coal. Obviously, anthracite is the best type of coal to burn in a train, yet this type of coal is by far the most expensive and supplies of this fuel are limited, so anthracite accounts for only 1% of America’s coal production as of 2020. Needless to say, any ideas of powering trains by burning anthracite are not realistic. Anthracite is best used for supplying the raw carbon for making steel, and anthracite’s shiny appearance and deep black color mean that this material is also used as a gemstone which called Jet, hence the term “jet black.”

Cost: $98.68 per ton.

The image above shows lumps of shiny anthracite coal. Image courtesy of fineartamerica.com

The image of above shows different grades of coal. Citation courtesy of maliksayourcoal.weebly.com

The image above shows different grades of coal. Image courtesy of researchgate.net

Cost of Biofuels

Admittedly, burning biofuels for energy is not as cheap as coal when it comes to producing the same amount of energy; however, in the event that large nations have collapsed and coal is no longer available on the local level in many locales, then looking for ways to harness biofuels and run steam trains with these energy sources makes perfect sense.

The Mighty Wood Chip

It is also worth noting that woodchips appear to be the most attractive option on the table when discussing different biofuel options for powering steam trains, and this is the case because making wood chips from raw biomass only adds a slight cost the to the final product. The process of turning raw wood into wood chip fuel typically involves first air drying the wood on designated dying wracks or letting raw woody biomass sit and dry on cement floors within covered spaces. After the raw biomass has been air-dried to around 30% moisture content, the next step is to shred the dried wood into suitably small wood chips; therefore, this process is not terribly energy intensive nor does it require a huge outlay in processing equipment compared to other biofuel energy options. One nice option offered by wood chip power is the fact that wood chips can be made at the same site where they will be burned, which lowers the overall cost of this fuel by eliminating a lot of transportation expenses associated with moving materials around from processing facilities to their final destinations.

By contrast, the process of making pellets or briquettes from any type of biomass requires first drying the material down to around 8—10% moisture content, then shredding this material into very small pieces, after that, the production process involves mixing the dried and pulverized material with a binding agent, then finally compressing the material into its final product. The process of turning biomass into pellets of briquettes also requires a huge amount of capital outlay to source the production equipment, and money also has to be spent on the power that is needed to run the production equipment. Maintaining the production equipment that is needed for making briquettes and pellets from any type of biomass also costs a fair amount of money, and the labor cost required for upkeep on the production facilities also has to be factored in, so any type of highly processed biofuel is going to be quite expensive when compared to wood chips.

The image above shows wood chips waiting to be burned at a power plant in New Hampshire. Image courtesy of archives.boston.com

The image of wood chips posted above comes courtesy of wikipedia.org

The Price of Wood Chips Sourced from Logging Residue

As listed on the website sevendaysvermont.com, the cost per ton of wood from logging operation waste varies between 20—30 dollars. Estimates for the cost per ton of wood sourced from logging waste was noted from an analysis of the price that the McNeil biomass power plant pays for raw wood supplies. The McNeil power plant, which powers the city of Burlington, Vermont; pays for logging waste wood that is sourced from within 100 miles of this woodchip-burning power station. According to the previously mentioned website, the McNeil power station is able to run year-round on almost no other source of fuel besides the chipped remains of waste wood that is brought in by trucks from nearby logging operations.

The price per ton of logging scrap wood is worth mentioning because this is the cheapest source of biomass fuel for powering Breitspurbahn trains; however, the catch is that there is probably not enough leftover scarp wood from commercial logging operations to keep large numbers of Breitspurbahn trains running continuously, so other sources of biomass will have to be found. The wood-energy.org website lists the national price of dry wood chips that have been salvaged from logging operations to be around $28 per dry ton.

The image of logging waste wood wood that is posted above comes courtesy of alderinvestment.com

The Cost of Plantation-grown Wood Chips

Admittedly, the cost of dry wood chips obtained from coppiced short-rotation popular and willow trees that have been deliberately grown as energy crops might vary a bit, but the general estimate is around $52 per dry ton according to wood-energy.com.

The image above shows coppiced trees. Image courtesy of forestrypedia.com

The photo above shows an orchard of coppiced willow trees. Image courtesy of crops4energy.co.uk

True, the cost of plantation-grown wood chips is a bit high compared to coal or even compared to wood that has been obtained from logging operation waste, but this source of energy is still promising because it offers the possibility for places that do not have nearby coal deposits to have their own locally sourced and sustainable source of energy. The only real requirement for producing huge amounts of plantation-grown wood chips is to have a local climate with a suitable amount of rainfall and the right temperatures. The advantage offered by coppiced willow cultivation is the fact that this type of agroforestry permits cultivation of a useful crop on land that is either too waterlogged for most crops to grow or simply has soil quality that is too poor for growing food crops. The other nice perks associated with willow cultivation include erosion control, water purification, toxin remediation, and wind breaks, plus willow trees can be grown in places where they do not compete with any food crops for space or resources. In many places, coppiced willow trees do not need to be irrigated, yet small amounts of fertilizer may occasionally be needed to ensure good crop yields.

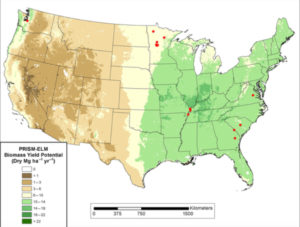

The image above shows the most promising areas for cultivating plantations of coppiced willow trees. The red dots on this map show specific growing test locations. Image courtesy of onlinelibrary.wiley.com

The image above shows the areas of American with the most promise for coppiced poplar cultivation. The red dots on this above image show testing areas. Image courtesy of onlinelibrary.wiley.com

The image above shows the overall potential for biomass production across America. Image courtesy of onlinelibrary.wiley.com

Cultivating poplar wood for energy uses is worth mentioning as well because poplar can grow in a wider variety of soil conditions and climates than willow; however, popular generally tends to produce less usable biomass per acre than willow. Willow may not be able to grow in as many different soil conditions as poplar, but willow trees are able to grow in some specific types of marginal soil conditions that popular trees would never be able to tolerate such as places with extreme winters and places with poor soil drainage, so it appears that cultivating willow trees as a dedicated energy crop is a more attractive possibility.

The image of coppiced willow being harvested by machinery comes courtesy of digitalcommons.esf.edu

The Cost of Wood Chips Sourced from Forest Thinnings

A “Thinning” is the term used to describe a logging operation where some of the trees are removed from a section of forest, but most trees are still left standing. Thinnings are an economically viable and sustainable alternative option to the practice of clear-cutting stands of forest, so the wood sourced from careful, well-planned, and mindful thinnings should be viewed as a sustainable and ecologically sound source of energy. The cost per ton of dry wood chips sourced from thinning harvests is generally between 30—48 dollars per ton as referenced on wood-energy.com.

The image above shows the basic premise of a forest thinning logging operation. Image courtesy of teagasc.ie

The Cost of Woodchips Made from Municipal Waste Wood

According the United States Department of Energy’s website, urban and suburban waste wood scavenged from demolished houses and buildings, broken pallets, discarded furniture, and old fences amounts to around 23 million tons per year across the United States, and the wholesale price per ton for scavenged municipal waste wood varies between 24—50 dollars per dry ton.

Image above image of municipal waste wood comes courtesy of the Guardian’s website.

The Cost of Compressed Wood Pellets

The current cost for a one-ton pallet stacked with plastic bags filled full of wood pellets is around 250 dollars in 2021, and this information is sourced from the homeadvisor.com website, and each individual bag of wood pellets retails for around 5 dollars for a 40-pound sack. So basically, it seems that the cost per ton of wood pellets is entirely too high when compared to the cost of raw dry wood that has been sourced from logging operation byproducts which cost around 28 dollars per ton. So, how much does the process of changing raw wood into compressed wood pellets or briquettes actually cost on a ton by ton basis?

The website of a company called Veco Plan Midwest provides some basic information concerning the economics of making compressed biomass fuel, and the equation breaks down that wood must be dried to at least 15% moisture content; whereas, fuel-ready wood chips typically have a moisture content of around 30%, but most pellet manufacturers consider a moisture content of around 8% to be best for making wood pellets or compressed biomass briquettes.

The image of wood chips posted above comes courtesy of whiteslumber.com

When manufacturing compressed biomass fuels, the incoming raw biomass product has to be ground into pieces that are small enough to be compressed into pellets or briquettes, which requires energy, and the drying process typically reduces the amount of material by around 50% in weight, so for every ton of raw wood received there will be a 1/2 ton of material that is ready to be pressing into pellets or briquettes. If a pellet plant uses its finished pellets to dry its own raw biomass stock, then this drying process will reduce the sellable amount of pellets by a minimum of 25%. Lastly, the cost of machinery maintenance increases the price of the pellets between 5—7 dollars per ton, and the cost of electricity needed to run the plant machinery typically adds 7—10 dollars per ton to the final product cost.

The illustration of the wood pellet making process comes courtesy of wood-pellet-mill.com

So, in summary, if the cost of raw wood is 28 dollars per ton, then the plant will have to sell each ton of pellets for at least 56 dollars just to break even on account of losing half of their wood weight from the drying process, then the cost of running the mill will have to be factored into the equation, so at a bare minimum another cost of 12 dollars per ton will have to be added just to cover the expenses associated with of machinery maintenance and the electric bills that are needed to run the plant machinery, which means that a plant that processes raw wood purchased at 28 dollar per ton would have to sell its product for at least 68 dollars per ton just to break even without making a profit.

The cost of paying back the investment on the plant equipment must also be factored into the final cost of pellet production, and the investment cost is around 500,000 dollars for every ton per hour of pellet-making capacity, so the overall cost of pellet production will always be more than double the price of the raw material. As of 2019, the website woodpellets.com lists the average cost for a ton of wood pellets to be around 245 dollars, which means that it may be cheaper to heat a house with wood pellets than with kerosene, but powering a steam train by burning wood compressed pellets or compressed wood briquettes is really too expensive to be practical.

The image above shows small-scale pellet mill machinery. Image courtesy of agicosolution.com

The Cost of Compressed Agricultural Waste Products

Estimates place the current worldwide production capacity for compressed biomass briquettes at around 230 billion tons per year, but as of the present, the only place that seems to have made a real investment in producing densified biomass briquettes on a large scale is India. A quick internet search for the cost per ton of compressed biomass briquettes made from food crop byproducts typically leads to Indiamart.com and Alibaba.com. The cost of finished compressed agricultural biomass briquettes from India varies from around 4,000 Rupees per ton to 7,500 Rupees per ton, which translates to 53—99 USD per ton.

The image of biomass briquette production comes courtesy of indiamart.com

The image above shows a screen capture of a sales listing for briquettes of compressed agricultural waste products on the India Mart website.

The U.S. Department of Energy lists the available tonnage of food crop waste products across America to be about 94 million tons per year which is sourced from the primary crops of wheat, corn, oats, sorghum, and barley that sell for about 50—60 dollars per ton with corn constituting 85% of this potential energy source.

The image above shows corn stover, which is the waste products that remain after corn has been harvested. Image courtesy of grows.cals.wisc.edu

After corn has been harvested by machine, the leftover remains of the corn plants can be gathered and put into bales by machine as well. Image courtesy of hayandforage.com

The IndiaMart website lists the source for most of their agricultural waste biomass briquettes as being mustard seed husks, but in places like Europe and North America agricultural waste items that are not sourced from the five key grain crops include commodities such as nut shells, peach pits, cherry pits, and olive pits which presently account for around 26 million tons per year across America. The U.S. Department of Energy’s website lists the basic cost of biomass that is not sourced from main cereal crops to be 40—60 dollars per ton. Excess animal manure is also listed on the U.S Department of Energy’s website, and this material is assumed to offer between 30—60 million dry tons of material per year across America at a price of 50—60 dollars per ton.

A 2016 report from the U.S Department of Energy that outlined the energy potential associated with turning municipal waste into briquettes of biomass, lists that there are around 3.3 million tons of yard trimmings produced annually across America that can easily be harnessed for energy at the cost of 60 dollars per dry ton. In summary, agricultural waste products wholesale at around 40—60 dollars per ton and offer the potential to be compressed into biomass briquettes, yet at a considerable additional cost; moreover, the basic cost of bituminous coal is around 50 dollars per ton, so coal is still a cheaper source of energy than discarded agricultural waste products that have not yet even been dried and compressed, much less transformed into refined solid biofuels. None the less, despite their comparative high cost, making biofuels from biological waste products offers a convenient source of energy in places where coal is not locally available.

Despite their seeming abundance, the process of actually turning agricultural waste products into usable compressed biomass fuels demands that the final products must sell for at least double the price per ton compared to the wholesale price per ton for the starting raw material, but then all sorts of other costs such as plant maintenance and transportation costs also have to be factored in to the final costs for compressed biomass fuels; thus, the overall price of compressed biomass fuels compared to simple wood chips makes the price of burning these fuels too high to be a practical option for powering steam trains.

Part 5. How Much Fuel is Needed?

Image courtesy of fineartamerica.com

When discussing how much fuel a Breitspurbahn-sized steam train would consume per mile or per operational hour, it is important to remember that dedicated freight train locomotives would be designed a bit differently than dedicated passenger train locomotive. That having been said, it is still worth having a discussion about how much fuel a Breitspurbahn train would consume per mile. A simple search engine query concerning how much coal a typical freight train burned per mile back in the day led to an entry on the Quora.com forum. The Quora forum post mentioned previously noted that in the old British 4-2-2 Stirling locomotives consumed about 60 pounds of coal per mile while moving at 60 miles per hour. 60 pounds of coal per minute translates to about four 20-pound shovel-fulls of coal being fed into the train’s fire box per minute by a stoker. At a rate of 60 pounds of coal being consumed per minute, the Stirling 4-2-2 would burn about 1.8 tons of coal per hour while moving at 60 miles per hour.

The photo above shows an old British Stirling 4-2-2 train. Image courtesy of wikipedia.org

So, the figure of 60 pounds of coal being burned per mile could theoretically be doubled for a Breitspurbahn-sized train, and this figure of doubling the fuel consumption for a Breitspurbahn-sized train is just a guess concerning fuel consumption numbers, so this assumed figure for fuel consumption on Breitspurbahn trains means that around 120 pounds of coal would be consumed per mile at a speed of 60 miles per hour. That having been said, if a Breitspurbahn-sized train were to have a GPCS type boiler system, then the fuel consumption would be at least 30% less, so the estimated coal consumption per mile for a proper Breitspurbahn steam train would only be 80 pounds; therefore, a Breitspurbahn steam train with a GPCS boiler would consume around 2.4 tons of bituminous coal per hour while moving at 60 mile per hour.

Concerning the fuel used per hour by a dedicated Breitspurbahn-sized passenger train, the best place to start when estimating this figure is to reference the coal consumed by the old British Mallard passenger steam trains which used to run at around 120 miles per hour. According to a post by Stephen Carey on Quora.com, the old British Mallard trains used to burn around 2.25 to 3.25 tons of coal per hour while running at full speed, so if that number should be doubled to determine the consumption rate for a Breitspurbahn train, which would equate to around 4.5—6.5 tons per hour; however, having one of Livio Porta’s GPCS boiler systems working would reduce coal consumption by around 30%, so the real consumption would be around 3.15—4.5 tons of coal per hour.

Image of a Mallard train courtesy of culture24.co.uk

Burning around 70% more coal in a Breitspurbahn-sized train would also necessitate having at least one additional stoker on the train crew, along with possibly needing one more service door to feed the train’s fire box. No doubt, having additional stokers on payroll would drive operating cost up a bit, but perhaps using an automated stoking mechanism of some type would be more cost effective than paying additional stokers.

As listed on the North Carolina State University Extension publications website, the gigajoule per ton rating for sub-bituminous coal ranges between 15 to 19, compared to 27—31 for regular bituminous coal, which averages to a 52—49% reduction in energy per ton when compared to burning less carbon-rich types of coal such as lignite or sub-bituminous. So, if a steam train that is equipped with a GPCS firebox were to burn either sub-bituminous or lignite coal, then this train would have to stock up on around 50% more coal to achieve the same energy levels as noted when burning regular bituminous coal.

As for price, sub-bituminous coal sells for around 15 dollars per ton, so even with a 50% increase in the amount of fuel needed when burning sub-bituminous coal, the cost of running a steam train on this type of fuel would still add up to a lot less than the total cost of running a train on conventional coal. $15 multiplied by 50% equates to 7.5 dollars, so the approximate cost per ton to compensate for the lower energy levels of lignite or sub-bituminous coal would equate to paying 22.7 dollars per ton. So, the real cost for producing the same amount of energy as that made by paying around 50 dollars for a ton of standard bituminous coal would be 22.7 dollars per ton when burning lower grades of coal; therefore, even at a 50% reduction in energy per ton when burning sub-bituminous coal is still an economical choice.

When factoring the consumption of biofuels, the cheapest and most convenient option for powering steam trains from biomass would be burning wood chips, so the energy value of wood chips would have to be compared against the energy value of burning basic bituminous coal to develop a meaningful cost analysis. According to the website called forestresearch.gov.uk, the energy contained per ton for wood chips is around 12.5 gigajoules; whereas, a ton of basic bituminous coal offers 27—31 gigajoules of energy. If 31 is divided by 12.5, then the result is 2.48, so let us say for simplicity that a train would have to burn around 2.5 times as many tons of loose wood chips by weight to achieve the same energy output as that of burning standard coal.

With the previous calculations in mind, a Breitspurbahn passenger train that is burning wood chips would most likely consume around 7.75—11.25 tons of wood chips per hour when moving at 120 miles per hour. As for differences in volume by weight when comparing wood chips to coal, the same website referenced earlier mentions that wood chips have 3.5 times the volume for the same weight when compared to standard coal, so a train that is burning wood chips would have to stock 2.5 times the weight in fuel compared to standard coal at three times the volume, so the total extra volume would equate to 8.75 times that of standard coal in order to achieve the same energy level. At a cost of 28 dollars per ton for wood chips that are soured from logging operation waste, the effective compensatory cost of running a steam train on wood chips would be 70 dollars per ton compared to the 50-dollar-per-ton base cost of burning standard coal; thus, burning wood chips that have been sourced from logging waste as opposed to burning regular bituminous coal results in a 40% increased cost in fuel.

If the wood chips that are used to power a Breitspurbahn train were sourced from plantation-grown and coppiced trees, then the compensatory cost would be around 130 dollars per ton as opposed to paying $50 per ton for regular bituminous coal, which translates to a 260% increase in fuel costs when a train burns wood chips that have been soured from biomass plantations. Indeed, running a Breitspurbahn train on plantation-grown wood chips would not be the most economical way to do things; however, powering a train by this method would offer a fuel source that is localized, sustainable, and non-polluting.

Lastly, the task of keeping a large Breitspurbahn train continually stoked with huge amounts of loose wood chips might demand a crew of stokers as large as 8, and having multiple stoking doors to feed this train’s boiler firebox would probably also be a necessity; however, developing automated stoking mechanisms for Breitspurbahn trains that burn wood chips seems like the most logical solution to this problem.

So, how would a steam train that is burning huge amounts of bulky wood chips store and then stoke this material at the rate that is needed to keep the train running? In answer, a train that runs on wood chips would need to be fueled by a series of hopper storage train cars that are connected to one another by a series of augers or conveyor belts. Using some type of auger or conveyor belt system to keep a train’s firebox properly stoked with wood chips as opposed to doing everything manually is also a good idea because wood chips tend to have a lot of dust on them; therefore, keeping an entire wood chip feed mechanism as enclosed as possible would be a good idea.

The image above shows a grain trailer with an auger attachment; admittedly, the trailer shown above is not destined to work as a train car, nor is it designed to handle wood chips; however, this basic design could easily be modified to serve as a fuel storage cars on trains that burn bulk wood chips. Image courtesy of brentequip.com

The image above is included to illustrate the basic principles behind the operation of augured bulk train cars. Trains that burn wood chips could easily store their fuel supplies in hopper cars that are connected by augurs. Image courtesy of flamanagriculutre.com

Part 6. Shipping Cargo by Breitspurbahn Trains

Image courtesy of practicalmachinist.com

Hitler and his cohorts originally imagined that the Breitspurbahn train network would function as an alternative to maritime shipping, so how many shipping containers does a typical container ship move per trip? The answer to that question is: 2,000—5,000 shipping containers are held on a typical container ship, and the largest of container ships as of the year 2020 hold upwards of 21,000 standard-sized 20-foot long shipping units. On the other hand, a typical Breitspurbahn train would only carry around 650 standard shipping containers, so the carrying capacity of an individual Breitspurbahn train would be a whole lot less than that of a container ship.

Image of a container ship furnished by theverge.com

So, what would be some advantages of using Breitspurbahn trains as opposed to moving cargo by ship? In answer, a single Breitspurbahn train has a markedly lower carrying capacity than even a modest-sized ship, however, a big train can move cargo over land in a more direct manner than a ship. For example, cargo that is transported on a Breitspurbahn network could be moved from China to Germany without ever needing contact with a ship, and cargo could also be moved by train from the East Coast of North America to the West Coast of North America without ever having to go near a large body of water.

Another example of the Breitspurbahn’s ability to take the most direct shipping route can understood by imagining a case where a ship travels from the South of China to Europe, and during this journey, this ship would need to go around the tip of the Malaysian Peninsula, traverse the southernmost point of India, go around the south end of the Arabian Peninsula, then pass through the Suez Canal in Egypt; therefore, traversing an oceanic route from China to Europe demands traveling thousands of miles around various land masses in an indirect manner. Likewise, if a ship were to make a journey from the East Coast of North America to the West Coast of North America, this imagined ship would also have to travel thousands of miles to the south, traverse the southernmost point on the Florida peninsula, then cross the bottleneck of the Panama Canal; after that, this ship would have to travel thousands of miles back northwards to reach the coast of California. By contrast, a Breitspurbahn train would simply take the most direct overland route from the East Coast to the West Coast.

Another key advantage offered by the Breitspurbahn trains is speed. For instance, a Breitspurbahn train would be capable of making a direct overland trip from the east coast of North America to the west coast of the continent in a short 43 hours, provided that this train moves at 65 miles per hour without stopping nor making any unnecessary detours. Also, a container ship typically moves at around 25 miles per hour; whereas, Breitspurbahn freight trains would average around 65 miles per hour while also making more direct journeys than ships. Admittedly, a given Breitspurbahn train would carry much less cargo than a typical container ship; however, Breitspurbahn trains do not stand as individual units to the same degree as cargo ships; but instead, individual Breitspurbahn trains would function as components within a much larger integrated transportation network that would have a truly huge carrying capacity.

Image courtesy of maritime-executive.com

For example, a large Breitspurbahn rail line could easily have two tracks running in each direction and each of these individual train tracks could have many trains barreling along one after another at all hours of the day, so a continuous pattern of heavy Breitspurbahn traffic along multi-track train lines could move much more cargo than maritime shipping lanes on a month-by-month basis while transporting all of their cargo much faster. Consider this, the overland distance from Shanghai, China to Paris, France is 5758 miles, and if a Breitspurbahn train moves at 65 miles per hour, then the travel time between Shanghai and Paris would be a relatively short 88 hours, or about 4 days — provided this train were to make no stops! By contrast, a container ship takes 30—48 days to travel from Shanghai to Belgium by way of the Suez Canal, as listed on the sailhub.com website.

When analyzing the costs of shipping across points in North America, a 2017 article written by Harry Valentine and published on the Maritime Executive website listed the cost of moving a standard-sized shipping container for one nautical mile on a container ship as being around 80 cents. The Commerce Express website lists American shipping as of the year 2020 as being around 97 cents per mile for moving a standard shipping container on a two-tiered standard rail car that is specifically designed for moving shipping containers. By contrast, truck shipping rates vary between $1.50 per mile for journeys of more than 1500 miles to as much as $16.50 per mile for journey of less than 100 miles. So, in the article published in Maritime Executive that was mentioned previously, Valentine notes that moving one shipping container from the port of Long Beach, California to the port of New Orleans, Louisiana by container ship would require a seagoing journey of 4,355 nautical miles that would include a slow crossing of the Panama Canal, so the cost of moving one container from Long Beach to New Orleans would be around $3484.

The image above shows a screen capture from Google maps that shows the approximate distance from Long Beach, CA to New Orleans, LA. This map is intended to provide information concerning travel by car, but it will work as a reference point for travel by train as well.

In contrast to moving a shipping container along a maritime shipping route, an overland journey from Long Beach to New Orleans is 1901 miles as opposed to 4355 miles for a maritime journey, yet a Breitspurbahn train has more than double the carrying capacity of a regular train, so there would be a lower cost per mile to move a shipping container by this method, and this is the case because Breitspurbahn trains offer a lower cost per mile due to economy of scale factors — basically donuts are always cheaper by the dozen. So, with the economy of scale factor taken into consideration, let us speculate that there would be a minimum of a 20% reduction in shipping costs per container on a Breitspurbahn train as opposed to the cost of moving a shipping container on a regular freight train; therefore, the estimated cost per mile to move a standard shipping container on a Breitspurbahn line would be around 78 cents as opposed to 97 cents for travel by a regular train. With cost of 78 cents per mile, a Breitspurbahn railway journey that moves a standard container from Long Beach to New Orleans would only cost $1482, which is less expensive than travel by ship.

In this imagined case of transporting one shipping container from New Orleans to Long Beach, moving a container by Breitspurbahn would certainly be less expensive; however, the biggest advantage offered by the Breitspurbahn train as opposed to movement by ship would be speed, meaning that it would only take a Breitspurbahn train 30 hours to reach New Orleans on an express route. On the other hand, it would require at least 7.5 days of travel time for a ship to reach New Orleans from the port of Long Beach, California and this travel time is calculated without adding the additional transit time required for a Panama Canal crossing.

Keep on Trucking

A Breitspurbahn train designated for moving freight would average 65 miles per hour, but a truck averages the same speed on an interstate highway, so a Breitspurbahn train would have no real advantage over a truck in terms of basic speed, yet a train can travel continuously and a truck must stop to allow the driver to sleep and to take mandatory driving breaks, and this is the case if only one driver is transporting the load. On the other hand, a truck that moves long distances with two drivers would be faster than a truck that has only one driver, and this is true because a two-driver truck wound not have to stop moving for sleep time, yet stops for refueling would still have to be made along the way and mandatory driving breaks would still have to be observed. So, even with two drivers on payroll, a truck that is transporting a shipping container would still have to make periodic stops, plus the cost for hiring a second driver would increase the rates from 29 to 40 cents more per mile.

Image courtesy of capitalwithstrategy.com

Given the need for trucks to make stops, travel by Breitspurbahn train would still be a bit faster than shipping by truck over long distances, plus the Breitspurbahn train would also offer much cheaper shipping rates due to having lower labor costs on a container by container basis and the fuel consumption per mile to move a shipping container by Breitspurbahn would also be much lower than that of a shipping by truck. So, in summary, the economy of scale and speed offered by Breitspurbahn trains would make this mode of shipping an attractive alternative to both maritime shipping and travel by truck.

Why are Trucks Still Used?

Despite their relatively high transportation cost, hiring truck companies and paying individual trucking contractors to move cargo is still a popular shipping choice because trucks offer their clients very flexible and direct access to final arrival facilities for individual shipments; whereas, shipping something by train requires that the cargo pass through loading yards before departure and after arrival, which slows the shipping process down considerably. The other problem with trains is that once a shipment has arrived at its destination, whatever was moved by that train typically still has to make the final leg of its journey by truck. For example, once a shipping container has arrived in New Orleans from Long Beach by way of train, a truck driver still has to move that container to the intended facility, and this final trip by truck can be time consuming and expensive in its own right. For example, the final part of a shipping container’s journey from the train yard to the end-user’s location could easily demand a trip out to a small town that is more than 100 miles from the train yard that is not connected by rail line.

Part 7. Using Breitspurbahn Trains for Passenger Transport

First, let us acknowledge that there is simply no way that big Breitspurbahn trains could possibly compete with air travel when it comes to the factor of speed. As of now, a typical jet airliner travels at a cruising speed of around 550 miles per hour and it is important to remember that a passenger aircraft is not limited by factors such as bodies of water or mountain ranges getting in the way, so journeys by aircraft are always going to involve taking the most direct route possible. As for travel by propeller plane, a good and modernized propeller-driven passenger liner would offer less expensive travel costs due to increased fuel economy, but even a very fast propeller-driven passenger airplane would only travel at around 400 miles per hour, so even a slower but cheaper propeller-driven aircraft travel option would still dust trains when factoring for speed.

As for the speed of trains, super-fast bullet trains have been in service in Japan and Europe for many years now, and the fastest of these super trains move at around 220 miles per hour, so a dedicated Breitspurbahn passenger train that moves at only 120 miles per hour would seem rather slow by comparison. So, what advantages would a Breitspurbahn train offer for travelers as compared to travel by aircraft and bullet trains?

How Fast can a Steam Trail Move?

A quick internet search for the fastest steam trains from yesteryear reveals that there were officially more than 10 models of steam train that were able to travel at more than 100 miles per hour continiously. The website ba-bamail.com provides a list of the fastest steam trains on record, and the winner is the old British Mallard train that set the official speed record for a steam train by clocking 126 miles per hour. As listed on Wikipedia, the A4 Mallard officially broke the speed record for a steam train on July 3, 1938 while traveling on a downward grade of the Stoke Bank which is located south of Grantham along the East Coast main rail line. Many rail enthusiasts claim that the Mallard was never really the fastest steam train to see service because the official record was broken on a downward grade and this train took boiler and piston damage as a result of running at 126 miles per hour.

The above photo of an A4 Mallard train is sourced from locomotive.fandom.com

On the other hand, the German Reichsbahn Class 05 steam train was officially clocked at 124.5 miles per hour while traveling on flat ground, and this train also took no damage from setting this earlier speed record on the 11th of May, 1936. The Reichsbahn Class 05 train that set the speed record in 1936 achieved this speed while hauling 197 tons along the Berlin-Hamburg line. The Reichsbahn Class 05 train was hauling a lighter load than the 240 tons which the Mallard was pulling when it set the official speed record. The Reichsbahn Class 05 was reported to have routinely traveled at more than 120 miles per hour on scheduled trips between Hamburg and Berlin without ever incurring any equipment damage, so some would argue that the Class 05 was really faster than the British Mallard train. As listed on Wikipedia, there were also several reports stating that the old American Pennsylvania Railroad class T1 steam trains periodically traveled at around 140 miles per hour on passenger runs, but these claims have never been officially verified.

It is also worth noting that the old German Class 05 trains has the largest drive wheels of any steam train, and having large drive wheels is considered to be one key factor that gave these trains their great traveling speed; however, a Breitspurbahn-sized train could easily have even larger drive wheels than either the old Mallards or the Class 05 trains which could easily furnish regular cruising speeds of more than 120 mile per hour.

The image above shows a photograph of a Reichsbahn Class 05 train. Image courtesy of flickr.com

Image of a Reichbahn 05 train furnished courtesy of Edward Pupek on Flickr.com

The Price Factor

It seems that the Breitspurbahn trains would offer passengers one big advantage over all other modes of transportation across land, and this advantage is low travel prices. The Breitspurbahn network could offer cheaper travel prices because moving by Breitspurbahn train would be rather inexpensive if economy of scale factors were present. For example, a typical Breitspurbahn train that is built for passenger transport would be able to comfortably move between 4,000 and 6,500 passengers, so the fuel prices, the labor costs, and the equipment maintenance expenses associated with moving one person for one mile would be very low for this mode of travel. It is also theoretically possible that Breitspurbahn train tickets would even undercut the cost of bus tickets for long distance travel.

As of now, a quick internet search reveals that the cost of a Greyhound bus ticket from Los Angeles to New York is around $249 for a journey of around 2789 miles as sourced from the Grreyhound bussline’s official website, so this breaks down to a travel cost of around 9 cents per mile for travel by long-distance passenger bus. An internet search which landed on a New York Times article from April 14 of 2020 that was written by Quoctrung Bai and Sarah Kliff also notes that an average airplane ticket from Los Angeles to New York costed around 350 dollars in 2019, and this cost reflects prices before the Covid-19 affair crushed peoples’ travel plans in general and then forced the airlines to offer artificially low airfares.

So, given the more accurate pre-Covid cost of an airplane ticket from Los Angeles to New York, we can surmise that the cost of an airline ticket was around 13 cents per mile in more normal times. A search of the Amtrack website reveals that the pre-Covid price of economy travel by train has historically been lower than that of economy class travel on airplanes, yet the cost of train tickets has still been historically higher than the cost of tickets on long-distance passenger busses.

Unfortunately, travel by train has been much more expensive than travel by aircraft if one chose to book a ticket that included access to a reserved cabin as opposed to just a seat. To make matters worse, the overpriced cabins offered on American Amtrack trains do offer some privacy, and these somewhat pricy train cabins do additionally provide better sleeping accommodations than that of simple train car seats, yet relatively costly train cabins are still rather cramped and not very comfortable; therefore, most people now conclude that the relatively high cost, slow travel times, and comparative discomfort of railway journeys makes moving by train an unappealing option compared to air travel.

According to the website virail.com, the average cost of a train ticket from Los Angeles to New York City is around $225, and a Google Maps search indicates that the distance between New York and Los Angles is around 2794 miles, so the average cost per passenger mile for train travel is around 13 cents for a basic train seat, which is about the same cost as travel by aircraft, except without the speed.

The Discomfort Factor

The second factor to consider for travel by Breitspurbahn trains is the issue of passenger comfort. So, we can say that before the Covid-19 episode, travel by bus was the cheapest way to move over long distances across land, yet travel by bus has historically been something that people have avoided due to this mode of transportation being rather slow and uncomfortable compared to other modes of travel. For example, it typically takes around 69.5 hours, or just under three days, to travel from Los Angeles to New York on a Greyhound bus that is contracted to run on a designated express route that makes minimal stops; this information was listed on the wanderru.com website. If travel by busses that are designated as “Express” is still a bit cumbersome and slow compared to other modes of transportation, then imagine taking a regular non-express bus ride from one end of American to another where the bus makes endless stops in one small town after another and switches drivers one after another. As anyone who has made an express bus trip from one end of America to another will attest, these types of trips are far from pleasant because the bus ride is not only long, but it is also cramped, bumpy, and smelly.

The Problems with Travel by Bus

On a typical bus trip, the restroom is cramped and filthy and the seats are basically uncomfortable as well as stained, rather dirty, and typically a bit smelly; plus, bus seats do not recline back very far, so whatever sleep a person can get on a long-distance bus ride will inevitably be intermittent and inadequate. Travel by bus is also rather noisy, plus the lack of privacy in the buss’s main compartment means that during the night hours a typical passenger will have to contend with other people snoring, farting, talking, and perhaps listing to music a bit too loud. As for the bathroom issue on busses, it is not uncommon for passengers to find themselves forced to wait in line to use the bathroom because only one toilet must suffice for as many as 30 people over a period of days. To make the situation even worse, couples may sneak into the bathroom for a bit of low-rent sex, but while a given pair of star-crossed lovebirds are occupying the buss’s filthy defecation closet in order to get their rocks off, this amorous pair will also be holding up traffic for people who urgently need to release some pent-up bodily waste; needless to say, these situations inevitably create some conflict.

Let us also not forget that some passengers will be riding busses with babies and small children in tow, so this state of affairs will make for a much noisier and more grating journey for everyone. Bus travel is also uncomfortable because the main cabin is not only cramped, but it is also constantly shifting as the vehicle moves, so bus passengers are basically forced to stay seated for long periods of time, which leads to sore rear ends, irritated spinal cords, and cramped limbs.

Image of riding an a Greyhound bus courtesy of rueters.com

Additionally, on long bus journeys, meals are sort of makeshift because food is generally not provided on busses, and any food at all will most often only be available at a few intermittent stops along the way. Traveling over a period of days on a bus also nixes the possibility of proper bathing, so long distance busses soon degenerate into little more than holding cells filled with grimy and smelly passengers. Another factor to consider is that bus travel attracts a lot of shifty people who are drifters, plus the down-and-out are also known to travel by bus, so at least in America, long-distance travel by bus is a lot like residing in a rolling bad neighborhood for a few days.

Image of a Greyhound buss’s riding cabin courtesy of halfwayanywhere.com

Concerning the topic of stowed luggage on bus trips, the passengers riding on busses cannot access their larger luggage while the bus is underway, and it is also not unusual for law enforcement agencies to search the luggage of bus passengers during routine stops at bus stations. Law enforcement officials are often looking for illicit drugs when they search the stowed luggage of bus passengers; however, searches for other items such as illicit firearms and even smuggled meat products are not unusual.

Admittedly, in Europe and the better parts of Asia such as Korea and Japan, travel by bus is not so dreaded, but in Europe and Japan the travel distances are typically much shorter than they would be in America, and interestingly, India has also made a more recent societal investment in upgraded bus travel. And unlike in American, places such as Japan and Europe have made a societal investment in offering the public better-quality travel busses with good seats, smoother rides, reduced noise, and really good travel busses also offer second-level lounges with settees, tables, and sun roofs; that having been said, places like North America, South America, and Australia generally have no such offerings.

Image of Greyhound busses courtesy of wanderwisdom.com

In America and elsewhere, a few companies have now arisen that offer luxury bus travel which target a customer base of people with money who are truly fed-up with the process of flying; however, travel on these luxury bus lines is still relatively expensive, and despite the comparative luxury travel that these upscale busses offer, even very fancy busses are still not a particularly comfortable travel option over long distances. Fact is, even rather luxurious busses are still cramped compared to traveling by train, and busses in general are always slow compared to travel by aircraft and bullet trains; plus, travel on luxury busses that provide good meal service, nice seating, clean bathrooms, and paid attendants is not cheap.

Interior of a luxury travel bus in Japan. Photo courtesy of job.co.jp

The image above shows the interior of a Vonlane travel bus. Vonlane is a company that operated comfortable busses that make regular routes between all 5 major metropolitan areas within the state of Texas. Since opening for business in 2014, Vonlane has become a bit hit with businessmen who fly frequently. Image courtesy of austin.culturemap.com

The Problems with Travel by Aircraft

Image courtesy of nytimes.com

As for travel on airplanes, the actual travel arrangements themselves are not much better than those of busses, except travel on airplanes typically — and mercifully — lasts for shorter durations, so the problems that are endemic to riding on busses are simply not as intensified during air travel. For example, the bathrooms on airplanes are also typically cramped and not very clean, plus idiotic people also use airplane bathrooms as grimy makeshift Sri Lanka sex motels, which prohibits others from defecating. And just like when riding on busses, the coach-class seats on airplanes are generally not very clean, nor are these bargain-priced seats very comfortable; plus, just like when riding on busses, coach-class seats on airplanes do not recline back very far; thus, sleep on airline flights is often rather bad and intermittent, just as it is on busses.

Airlines do typically offer their passengers food, but it is usually not very good, and like travel on busses, travel on airplanes involves having to listen to people playing music too loudly on their headphones, talking, snoring, and farting, etc. As anyone who has done any significant amount of flying can attest, traveling on these outsized aluminum cans when babies or small children are along for the ride can be rather unpleasant. And just like with busses, when passengers travel on airplanes, the planes shift around a lot and the cabins are rather cramped as well, so airplane passengers are also forced to stay seated for long periods of time without being able to move around or stretch their limbs.

Now crowded airline flights have the added bonus of requiring everyone on board to wear dust masks during the duration of any given flight. Image courtesy of dw.com

Flights on early aircraft were not pressurized, so passengers had to endure the cold and thin air that comes with being at high altitude; for example, passengers on early Zeppelin flights were issued fur coats for their journeys; however, airliners today all have pressurized cabins. Despite today’s airline cabins being pressurized, these same flying aluminum bins still offer their passengers the experience of breathing air that is very dry and has the atmospheric pressure that is the equivalent of being at around 10,000 feet, so people who ride on airliners often arrive at their destinations feeling unusually tired and dehydrated. True, the most up-to-date airliners have improved their cabin air quality markedly over the years; regardless, passenger airplanes still provide air quality which mirrors that of sitting on a modestly high maintain top in Tibet during a summer day.

Airlines also have the drawback of forcing passengers to limit their take-along belongings in general, and this is especially true inside of airplane passenger cabins which typically restrict riders to carrying only one rather small carry-on bag, so when traveling by airplane, people really cannot take very much stuff along. Travel by airline also typically requires passengers to arrive at least two hours before their flight is scheduled to depart, and the process of checking in to the airport, passing through long and cumbersome security lines, and registering luggage also typically takes more than an hour, so the whole tedious process of boarding an airline flight would test patience of an accomplished senior Buddhist monk.

The joys of airline travel. Image courtesy of apnews.com

To make matters a bit worse concerning the travel experience at airports, after passengers have arrived at their final destination, they must then go to the baggage claim and wait to recover their checked-in luggage. Mercifully, the process of recovering checked-in luggage is usually not overly taxing, nor is the process excessively time consuming; however, being forced to deal with lost or damaged luggage is not unusual, and as Western countries continue to fall apart, the prospect of experiencing theft from checked-in luggage continues to grow. Another issue to note is that while passengers are traveling by aircraft, they cannot access their checked-in luggage.

Travel by Regular Train

As for travel by train, trains are generally faster than busses when traveling between the same cities, and trains also offer passengers the possibility of getting up and moving around during the journey, which makes the experience of traveling by train a bit more enjoyable. Trains also offer their passengers restrooms which are much larger and cleaner than those found on busses or airplanes, and the bathrooms on trains are also typically not prone to delays caused by people getting their freak on, plus trains typically provide decent enough dining accommodations which are usually available at all times. The drawbacks to train travel include higher ticket costs relative to busses — at least for basic seating — and trains also furnish slower travel times relative to aircraft. Let us also keep in mind that the cost of travel by train becomes quite expensive when people start paying for private cabins, so train travel with private cabin accommodations is both slower and more expensive than travel by aircraft.

The image above is a screen capture from the Amtrak website. This screen capture shows the different prices for a train ticket from Los Angles, CA to New York, NY on February 12, 2022. Note that the cost of a basic train ticket is about that of an airline ticket, and the sleeper cabin options are quite expensive.

The above image shows present coach-class seating on Amtrak trains. Image courtesy of archived.curbed.com

The photo above shows an Amtrak Business Class seating area. Image courtesy of airlinereporter.com

The image above shows a pricey Amtrak sleeper cabin. Photo courtesy of commons.wikimedia.org

Breitspurbahn Factor

Travel on a mega-train that averages 120 miles per hour and moves around the clock has the potential to offer the public an enticing travel option that potentially offers a cool cocktail which artfully blends price, comfort, and speed. In theory, economy class Breitspurbahn travel tickets would offer passengers comparatively comfortable accommodations such as large and fully reclining seats, the ability to walk around during the trip, anytime access to a decent cafeteria, plus access to full-sized walk-in communal bathrooms that would include shower booths, and all of this comfort would potentially be available for a lower price than that of basic bus tickets.

Travel on the Breitspurbahn trains would also offer passengers with a bit more money at their disposal the option of booking cabins of various sizes for prices that are competitive with those of airplane tickets, and for those with access to a lot of money, travel on the Breitspurbahn network could easily offer access to luxurious and roomy rolling villas. Remember, a single Breitspurbahn train car would be 138 feet long, 23 feet high, and around 19 feet wide, so these measurements offer interior designers plenty of space to go crazy with ideas. Hitler’s original vision for his mega-trains included offering the passengers access to gyms, movie theaters, bars, night clubs, plays, live music, and fine dining accommodations, so there would be plenty of room on a Breitspurbahn train for all kinds of traveling luxuries that are usually reserved for ships.

The image above is an actual artistic rendering from German archives for the proposed dining cars in Breitspurbahn passenger trains. Image courtesy of deviantart.com

The image above shows another actual German conceptual sketch of interiors on Breitspurbahn passenger cars. Image courtesy of anyskin.tumblr.com

An actual concept sketch of a Breitpurbahn travel cabin. Image courtesy of gadzetomania.pl

Basic Time Issues

As for the issue of speed, if a Breitspurbahn passenger train moves at an average of 120 miles-per-hour, then this rate of continuous movement actually make travel between short to medium distances surprisingly quick. For instance, the distance between Sacramento, California and Salt Lake City, Utah is 694 miles, and at an average traveling speed of 120 miles per hour, a Breitspurbahn train could theoretically make this journey in around 6—7 hours.

Likewise, the distance between Sacramento, California and Chicago, Illinois is 2045 miles, so it would realistically take a Breitspurbahn train around 20 hours to arrive from either starting point on this trip. Admittedly, taking 20 hours to travel from Sacrament to Chicago seems laughable when compared to the travel times posted by bullet trains, and the sort of travel times that would be posted by Breitspurbahn steam trains are especially laughable when compared to the travel times for aircraft; however, travel by Breitspurbahn would mostly focus on moving by night.

For example, a hypothetical 20-hour journey from Chicago, Illinois to Sacramento, California would begin at 5:00 PM in Chicago and end at 1:00 PM the next day according to Central Standard Time, except Sacramento is on Pacific Standard Time, so a train that left Chicago would arrive would arrive at 11:00 AM the next day on Sacramento time, and this arrival time would be the functional equivalent of catching an early-morning “red eye” flight out of Chicago, except a passenger who traveled on a Breitspurbahn train could have eaten a decent dinner, watched a crummy movie, worked out in a gym on the train, taken a shower, and then slept in a decent bed over the course of that evening while the big train rolled past amber waves of grain. So, the real appeal of travel on a Breitspurbahn train would be the possibility of traveling while sleeping rather comfortably, so there could be minimal waking hours wasted on travel.

As another example, the distance between Los Angeles, California and Vancouver, British Columbia is 1277 miles, so it would take a Breitspurbahn express train around 12 hours to make this trip if a train averaged 120 miles per hour; therefore, a Breitspurbahn train could leave Los Angeles at 7:00 PM and arrive in Vancouver at 7:00 AM the next morning with a train full of relatively happy, relaxed, and well-rested passengers. As for shorter journeys, such as taking a trip between Indianapolis and Washington D.C, the distance for this journey is only 576 miles, so a Breitspurbahn train could knock this excursion out in only 5 hours; however, the option to board the train at 7:00 PM and disembark as late as 9:00 AM the next morning would still be on the table in order to furnish the train’s passengers with the possibility of getting a good night of sleep inside of their reserved cabins. That having been said, passengers could also choose to be alerted once their train has arrived at its destination if they should wish to leave the premises immediately. The possibility of letting passengers sleep-in a bit after arriving at their destinations could be facilitated by building early-arrival parking spots for these huge and fast trains.

The image above is a screen capture form Google maps that provides basic driving directions from Los Angeles, CA to Vancouver, BC.

Other Time Factors

The problem with making the sort of simple travel calculations that were mentioned previously where a train’s speed is just multiplied by the travel distance is the fact that solving basic math problems concerning travel times and distances fails to take weather conditions and mountain grades into consideration. Weather delays can affect all types of transportation, including aircraft, so there is no special issue with weather delays for trains. For example, snow storms typically ground all airline traffic and these delays can last for days and leave passengers stranded in far-away places. Likewise, heavy snow buildup can stop trains from moving until large amounts of snow have been cleared from rail lines.

Image courtesy of cnn.com

True, weather issues can delay practically any type of transportation, yet unlike with air travel, cars, trains, and busses are often delayed when they have to traverse steep mountain grades. For example, the journey from Los Angeles, California to Vancouver, British Colombia is 1277 miles, so if a Breitspurbahn passenger train were to average 120 miles per hour, then this journey should take around 12 hours, but a land-based trip between Vancouver and Los Angeles requires crossing more than one mountain range, so climbing long and steep mountain grades will inevitably slow trains down.

One potential solution to the problem of trains being delayed when crossing mountains is to make brief stops at the beginnings of mountain range crossings where other assist locomotives would attach themselves to the traversing train, which would translate to faster mountain crossing speeds. Once the network is in place, it is likely that Breitspurbahn trains would routinely make short stops before and after crossing ranges of mountains. True, the act of stopping to hook up assist locomotives would add time to rail journeys, and running extra assist locomotives would also drive the cost of travel up a bit; however, the boost in speed earned by including extra locomotives when crossing mountains would be appreciated.

A good ballpark figure for the time delay associated with crossing mountains on a Breitspurbahn journey from Los Angeles to Vancouver would be around 2 hours more of total journey time, which would boost average travel times for these trips from around 12 hours to a more realistic 14-hour travel period. The upshot of these 2-hour mountain-crossing delays would simply mean that Breitspurbahn trains would leave the station in Los Angeles at 5 PM and arrive in Vancouver, B.C. at 7 AM the next morning, which is still a decent travel arrangement.

Another time factor to consider is the issue of Breitspurbahn trains stopping for fuel or water along the course of a rail journey. In the past, steam trains have traditionally stopped for water about every 200—250 miles, yet with a Porta GPCS system in place, a steam train would only be using 70% the water as before, so there could easily be an added 30% to the distance between water stops; therefore, a Breitspurbahn steam train could stop for water every 325 miles on average. It is also worth noting that the old British Elizabethan Express ran from the King’s Cross rail station in London to Edinburgh’s Waverly train station in Scotland from 1953 to 1961, and steam trains ran along this famous train route for 393 miles without making a single stop, so it is quite possible that larger Breitspurbahn locomotives which are equipped with Porta’s GPCS fireboxes could travel even longer distances without stopping.

Designated water stops could also function as places where steam-powered Breitspurbahn trains would take on more fuel in addition to steaming water, so the need for weighing a train down with heavy fuel loads could be reduced by making scheduled stops along travel routes. Realistically, planned fuel and water stops would rarely require more than about 20 minutes to complete, so these short pauses along planned routes would not be likely to add too much time to any Breitspurbahn’s travel schedule. Travel stops where fuel and water are taken on could also provide the time needed for additional assist locomotives to hook up to the main Breitspurbahn trains at the feet of mountain ranges, so scheduled stops before and after traversing mountain ranges could serve multiple functions.

Other Perks of Traveling by Breitspurbahn

One could imagine that travel on the Breitspurbahn network would be a lot like staying at a moving hotel, so overnight travel on the Breitspurbahn network could easily become a popular travel option. As for the issue of Breitspurbahn trains making longer trips of more than 1200 miles, such as journeying from Miami, Florida to Seattle, Washington; this is where travel by aircraft or perhaps travel by 200+ mile-per-hour bullet trains would be more attractive than travel on the Breitspurbahn; however, the low cost and relative comfort of travel on the Breitspurbahn network might be attractive enough to still draw a fair share of passengers on these types of long journeys. Encounters between people who are traveling for long distances on Breitspurbahn trains would also create its share of new business partnerships, friendships, and even romances of all types, so there would be an added social value attached to riding these large trains for periods of a few days as they cross vast continents.

Aside from simply offering passengers low-cost travel with a decent degree of comfort, the Breitspurbahn network would also offer riders the possibility of traveling with large amounts of relatively heavy and bulky luggage for fairly low costs while additionally offering riders full access to any of their packed items while in transit. As an added bonus, riding on the Breitspurbahn network could offer people the possibility of traveling with their cars so that they would not have to rent a vehicle upon arrival at their final destination, plus people could visit their pets, including their horses, while in transit.

Lastly, airlines often demand that passengers arrive at least two hours early to catch their airplane flights, but train boardings typically call for passengers to be present only half an hour before their appointed departures, and this is the case because the boarding process for both passengers and their luggage typically takes around 15 minutes at train stations. Boarding and exiting trains is so much faster than the process of entering and leaving aircraft because after arriving at train stations, passengers certainly have no need to visit baggage claims, and the disembarking process typically takes around 15 minutes as well for everyone on board. Anyone who has traveled extensively by aircraft also knows that the process of disembarking from a large passenger aircraft can take up to an hour, and the process of retrieving luggage at the final destination can take even longer than an hour, yet the process of having all the passengers on board disembark from a train typically lasts less than ten minutes because trains have so many exits along their length.

Conclusion

Building large steam trains that harness the most up-to-date steam engine technology that was developed by Livio Dante Porta and Andre Chapelon, do offer a worthwhile cargo shipping options and a great passenger travel option in a post collapse world of the not too distant future. As mentioned earlier in parts 1-3 of this same series, building larger trains that are of the same size as the Breitspurbhan network which was envisioned by Adolf Hitler and Albert Speer would also make sense due to economy of scale factors. As stated earlier, building and operating fewer large trains is more economical than operating a larger number of medium-sized trains. Maintaining larger trains requires less manpower and demands less fuel, plus using few train tracks that are designed to accommodate a smaller number or larger trains equates to lower track upkeep costs. In summary, now would be a good time to start making plans to build and operate regional networks of Breitspurbahn-sized steam trains.

The above image shows train crewmen from the Harz steam train line in present-day Germany. The future is the past!

5 Responses

I must state here that I could very well have taken down and read a vast section of the old encyclopedia Britannica from my library shelf and I would most assuredly never have been as much enlightened, educated and made informed as I have been with this article from our mutually esteemed Mr. James Rousse with regards to this particular subject at hand. I have found myself reading and rereading this exceptional followup article to his previous one over and over again these past several days and I must confess his brilliance as both a writer and researcher on this subject matter impresses me immensely and is, as a consequence, most assuredly very much appreciated by this one particular person in myself. Thank God there are individuals out here in this larger world whom still think and execute his/her educational talents for the truly honest benefit of those of us whom want to be kept informed, as well with the enlightened benefit of such fine writing skill and excellent grammatical talent – something I, personally, could always utilize with a serious helping hand now and then from others.

As with his previous article (In parts 1 – 3) we have yet much more information here (in parts 4-7) on a subject matter that if all of us were more seriously attuned to these facts and details many decades ago our world might very well have followed a very different pathway towards solving our transportation, energy, environmental and political (and cultural) concerns. Herr Hitler’s vision(s) leading us all toward a much better and more prosperous world for the mutual benefit of all of Europe, Asian and African cultures finds me contemplating so many, many variables in just how much more extraordinary and enriching life would be had Herr Hitler succeeded in his greater vision for the German Reich and the enhancements to the surrounding national landscapes bordering Germany – both near and far. Furthermore, I continue to find myself deeply impressed and astounded with regards to the extraordinary vision of Herr Hitler in how he was able to visualize so many all-encompassing aspects of his greater design(s) for both Europe and the Germanic peoples. Whether it be in his brilliance as an architect, master planner, political thinker, social reformer, environmentalist, (as well as a fine poet, writer, musician, etc) as each day, week, month and year passes by I become more “attuned” to the extraordinary consciousness of this great personage. God, I hope the world begins to awaken to what we sacrificed in the loss of this great man. Yet, it is still not too late to awaken ourselves to the enduring, eternal message Herr Hitler left for us as his great legacy – a legacy that will live on and on for many centuries upon centuries to come.

Thank you, Mr. Rousse, for educating me here again on another subject matter that was far and distant from the daily concerns that otherwise I may have never taken into account.

Note: Isn’t it amazing how things become more clear when viewed through the “rear view mirror” of decades, so to speak.

Hello Monika. As a recent awakee, I am new to this site and have just started browsing. I was directed here today by the delightful three-part interview with, and testimony of Gerard Lauck hosted by Brian Ruhr. Brian included a great set of links in his description. (Part 1 https://www.bitchute.com/video/ruCSWT5q9kha/)

I have bookmarked and will peruse the articles later, but let me say what a delightful and erudite comment by Frederick here, and also on the previous article (parts 1 – 3).

I am one of those who will pass on the truth to my own family and friends. Knowing my own journey, this has to be a gradual process as some of them still believe in wearing masks – what a clever exercise in mass hypnosis and psychosis.

All the best.

PS – I wish there was a Like button to acknowledge such articles and excellent comments.

Thanks so much, Julius! Welcome!

Frederick’s comment is almost as impressive as James’ essay! Great minds compliment each other, as it were. Monika and I are waiting to do a video interview with Frederick but his Zoom test didn’t work.

The following video is an anti-German (anti-“Nazi”) English propaganda hit piece – Its ugliness – the inherent envy and openly displayed hatred does the narrator no favor… It is a dishonor!

Calling the visionary project of the Breitspurbahn “insane” speaks of ill will, and petty narrow-mindedness

https://m.youtube.com/watch?v=zkuEP5iMRiM

Economic cooperation – development – prosperity and stability for Europe – Russia – Asia – the Middle East…

was a noble vision…

…

And what have we got instead?